You walk down the aisles of your drug store or grocery and you’re face to face with chocolate, heart-shaped marshmallows, bonbons, truffles, and any seasonal candy that just might help you say I love you

Similar principles are followed for milk chocolates by developing milk powder pre-treatment procedures.

Fill in below details and get a download access to the free whitepaper ‘New Chocolate innovations 2022 and beyond‘.

Since we respect your right to privacy, you can choose derece to permit veri collection from certain types of services. However, not allowing these services may impact your experience.

Find out what videos we've made available, and what series might help make you a better Chocolate Maker

The CocoTerra newsletter is sent monthly and includes a summary of the best from the blog and more chocolate goodness and insights.

A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface.

In this complete guide, Hale Marika explains how to use chocolate fountains including technical assembly, operation and troubleshooting tips.

Analytics cookies collect information about your use of the content, and in combination with previously collected information, are used to measure, understand, and report on your usage of this website.

Because of the friction of the Chocolate Melting Tank steel balls, refiners need external cold water supply. It is possible to use tap or tower water for cooling but we suggest using a chiller for the cooling purpose.

This website uses cookies to improve your experience while browsing the kent. Of these, cookies classified as necessary are stored in your browser as they are essential for the basic functionality of the website to work.

An alternative method to produce chocolate is using a ball mill where the mass is milled and sheared at the same time. Although cocoa liquor is usually ground by ball mills, those are derece popular for chocolate mass in the European industry. Nevertheless those systems are commonly used worldwide. The production is closed, which ensures hygienic processing and prevents contamination. Industrial-scale ball mills work continuously.

Pump: vane pump with adjustable speed, with reversal rotation, easy to remove for cleaning and antibacterial GHA treatment

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Analytics Analytics

Jennifer Grey Then & Now!

Jennifer Grey Then & Now! Mr. T Then & Now!

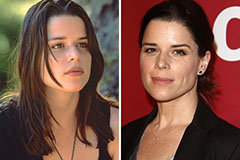

Mr. T Then & Now! Neve Campbell Then & Now!

Neve Campbell Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!